Drilling machining

This machining is used for carrying out holes.

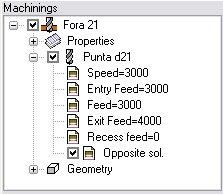

This machining requires entering: the descent drilling step (if the “Step” parameter is equal to zero, the hole will be carried out in one only pass), the dimension in Z from the hole bottom (Z Final Slowdown parameter) at which the speed is to be slowed down by entering the Lead-out Feed (not to risk damaging the lower side of the piece when the core drill sticks out of the slab) and finally, the "Z Lower" parameter, which enables defining how many mm the core drill will stick out of the slab bottom. Besides, in case a machining must be carried out with a considerable number of holes, it is possible to activate the option “Optimize” which will define the shortest path for carrying out all the holes. Like with all the other machining operations, also with drilling it is possible to modify the properties of each tool (Feed, Rotation, etc.) by selecting the + key next to the name of each tool.

Picture 190

Créé avec HelpNDoc Personal Edition: Rendez vos PDF plus sécurisés grâce au cryptage et à la protection par mot de passe